Sealing systems

We manufacture seals in our central sealing plant in Ninghai on currently 30 extrusion lines, co-extrusion lines with associated assembly processes.

Generous storage capacities give us the scope to meet almost all logistical requirements.

Sealing systems

Product portfolio

We develop unique composites and customized components for applications with high complexity.

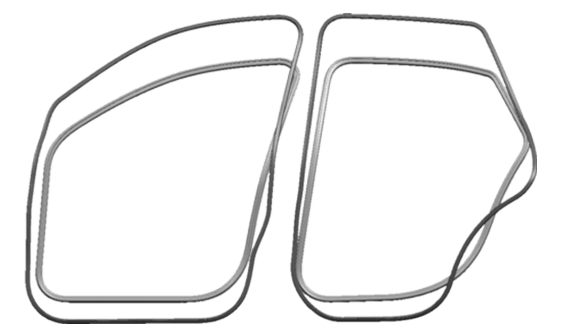

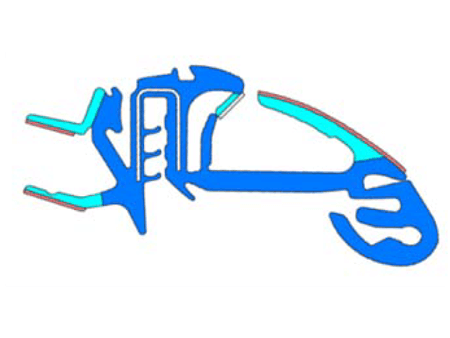

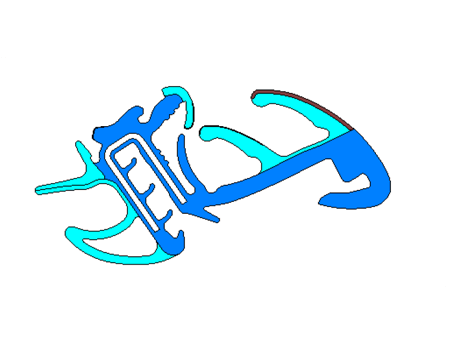

Front cap seal

Water box seal

Front window guide

flocked, bonded or coated

Window well cover

temperature resistant, high strength and extremely durable. flocked, bonded or coated

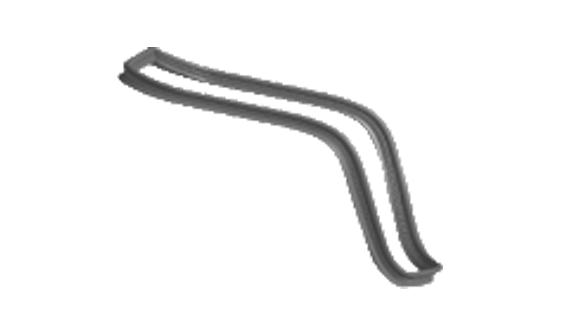

Lower door seal

Rear window guide

with injected glass

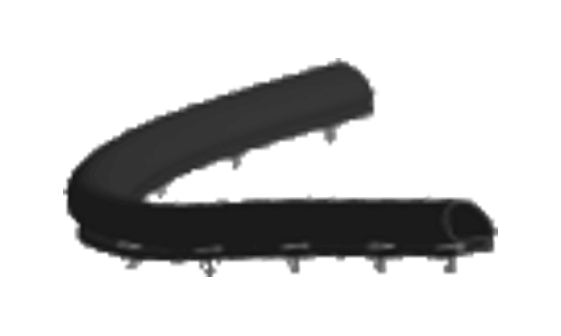

Sliding roof sealing

Sealing systems especially for the requirements in the area of the electric sliding roof flocked, glued or coated

Got Questions?

NBJX North America

+1 (734) 721 7340

NBJX North America as a business unit of Jianxin Zhao's Technology Co. Ltd. is one of the leading suppliers of modern sealing solutions for original equipment manufacturers. We meet the high quality demands of the industry worldwide, can manufacture large quantities and deliver them punctually and reliably according to modern standards.

In close cooperation with our customers, global development teams find innovative solutions to meet the demanding requirements in automotive engineering. We support our customers with a global network of competent and strategically placed manufacturing and logistics centers.

Jianxin Zhao's Technology Co. Ltd. has decades of experience and can provide the right composite material for all automotive sealing requirements. We provide support for diverse sealing applications from some of the world's major automotive manufacturers.

The engineering teams at JianXin Zhao's Technology Co. Ltd. have overcome numerous sealing difficulties in this industry and with their extensive automotive sealing expertise, they are an efficient source of advice and professional support when it comes to sealing solutions.

The automotive market relies heavily on effective seals at critical points. Extensive knowledge of elastomer materials and their properties is crucial for the development of optimal seals for the automotive industry. This is why we specialize in the development of customized elastomer parts and products, including seals and O-rings.

With a wealth of experience, our engineers can help you choose the right product sizes and materials for your application.

Analyses and studies

We develop unique composites and customised components for applications with high complexity. Surface treatments are also available so you can expect longer life and better performance from your sealing products.

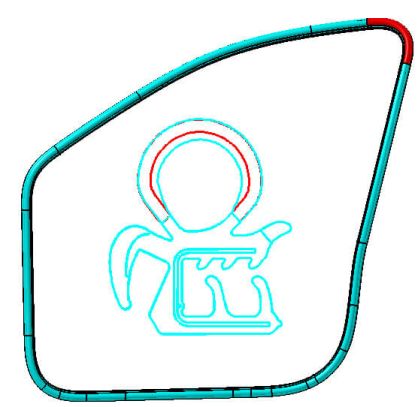

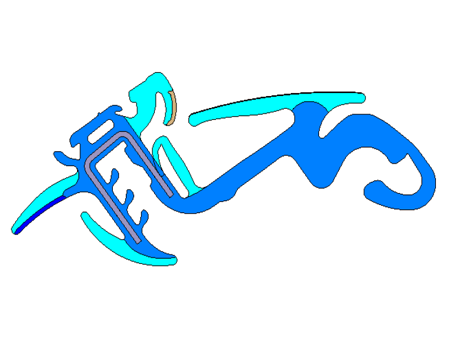

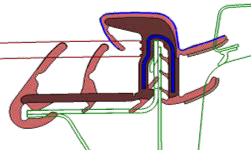

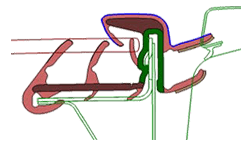

Jianxin Zhao's Technology Co. Ltd. technical team can conduct analytical studies and research to determine the suitability of specific sealing solutions. Using application parameters such as gasket material and geometry, FEM/FEA analysis can be carried out to replicate the real load situation as closely as possible.

This approach is used to support the development of new sealing concepts and to select the optimal material composite for the best result.

Process integration extrusion

We extrude rubber and thermoplastics of choice on carriers made of metal or plastic. Up to 6 different materials can be extruded together to form a profile. Depending on the requirements, we apply decorative strips online or flock the profile. We have mastered the production of seals with variable wall thicknesses in order to reproduce complicated geometries on the vehicle.

PE Film

Flock

Flock Tape

Extrusion Capabilities

EPDM & Alu Carrier

TPE + PP Carrier

Decorative strip

Decorative trim

Our Sealing plant in Ninghai

Also of interest?

Development process

After we have created and optimised the component design using CAE and defined the correct elastomer compound, prototypes of our components are made for validation prior to series production.

Elastomers

Since elastomers can deform significantly under load and then return to their original shape, our material experts develop elastomers with regard to durability and optimum performance.

Manufacturing

We develop the right solutions with our customers on site and have them produced in our factories in China.