Chassis Systems

Chassis structure components and modules

Reliable and tuned power transmission for driving dynamics, ride comfort and crash safety

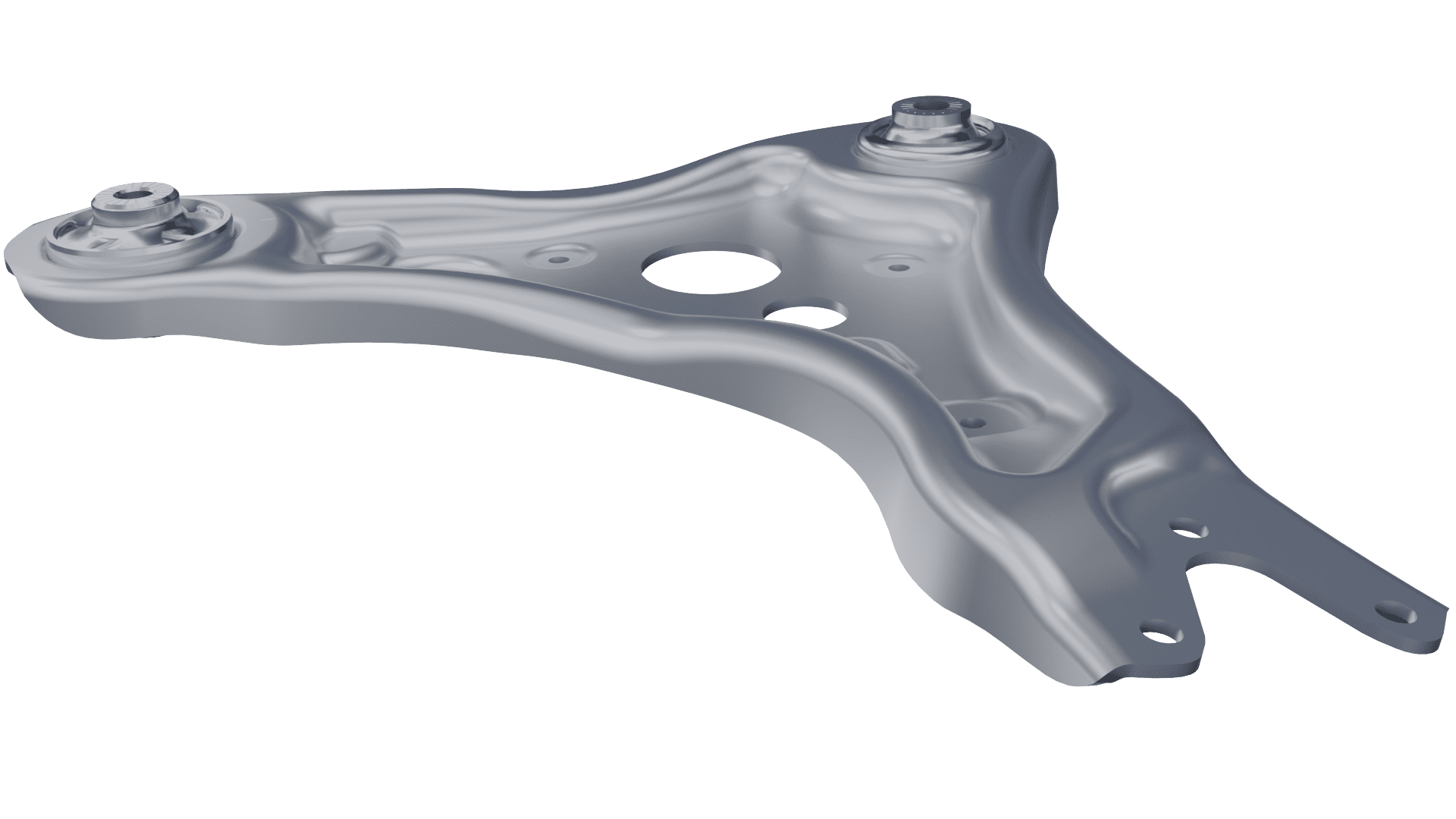

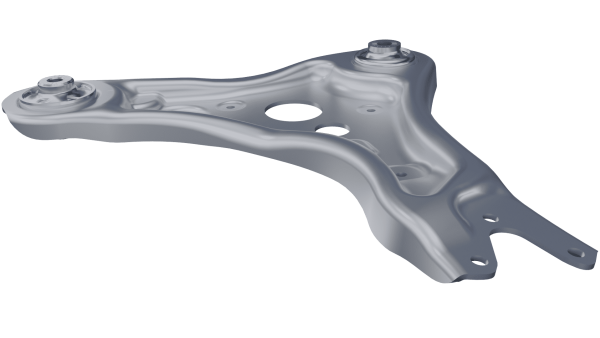

Control arm

Steel wheel suspension links in various designs, functions and assemblies.

Steering arms for different wheel suspensions are produced by forming, punching and welding. The components are coated and checked according to customer specifications and state-of-the-art. In-house developed and produced suspension bushings can be used in the assembly, but also from other suppliers if necessary.

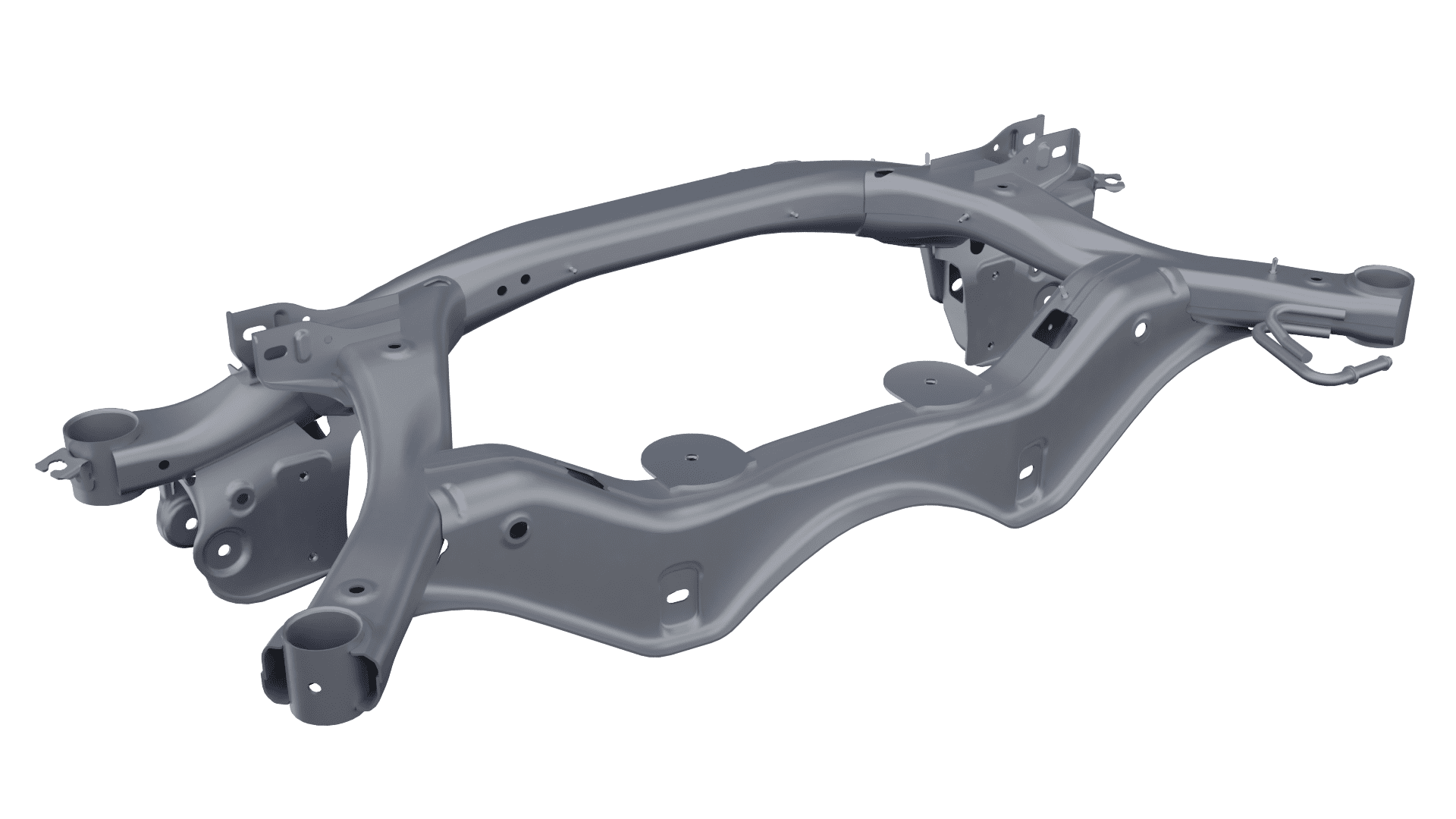

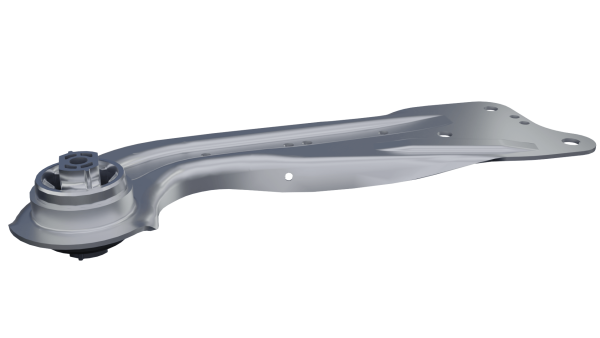

Twist-beam rear axle

The twist-beam rear axle: integration, simplification and cost optimization combined with exceptional functionality and durability

For many years and for several OEMs, we have been producing the sophisticated twist-beam rear axle component in all individual parts and as a welded assembly, ready coated/painted and, if necessary, completed with add-on parts such as steering arm bushings. Extensive experience and high-quality (automated) equipment guarantee the quality of this very demanding component.

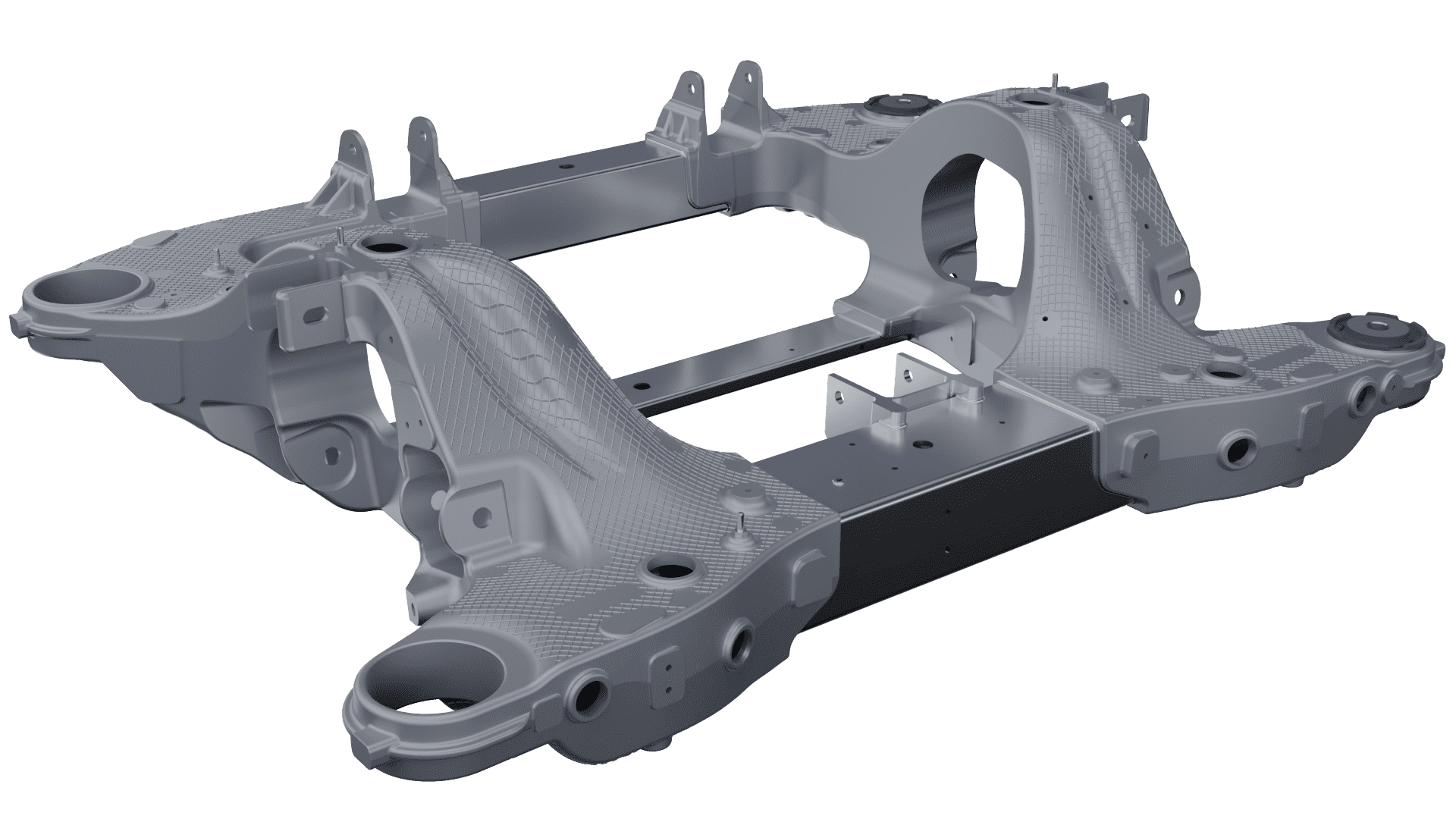

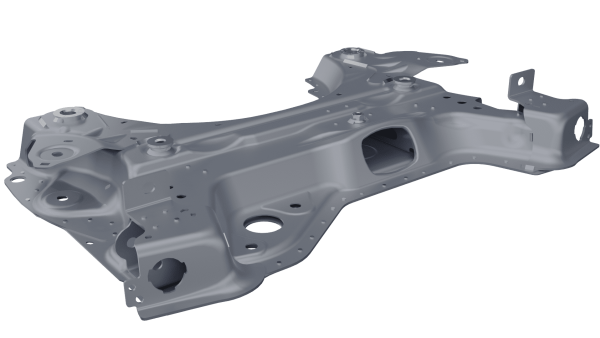

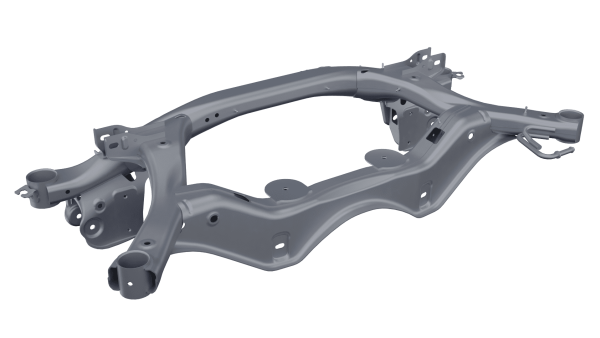

Subframe

Confronted with very many requirements and interfaces: Steel chassis subframe or chassis crossmember. The large number of OEM customers and variants confirm our competitiveness.

Time and again, steel is used as the material for chassis subframes or chassis crossmembers. For the high stiffness and strength requirements, combined with very narrow installation spaces, steel seems desirable. And especially in cost-sensitive countries and markets, this component may even be proliferated. Our experience, toolsets and testing possibilities are complete.

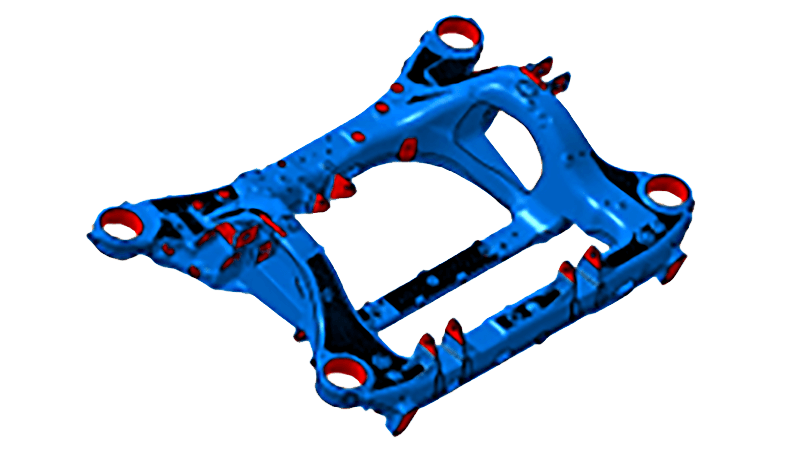

Aluminum subframe

For lightweight construction as a premise: Aluminum chassis. Aluminum casting according to our own development and production - as welded assembly from our hand to the customer.

If lightweight construction is a very high priority and the necessary installation space is available, solutions in aluminum are also designed and produced in-house. Many years of experience with many different components in the field of aluminum die-casting enable us to develop complex aluminum structures quickly and reliably.

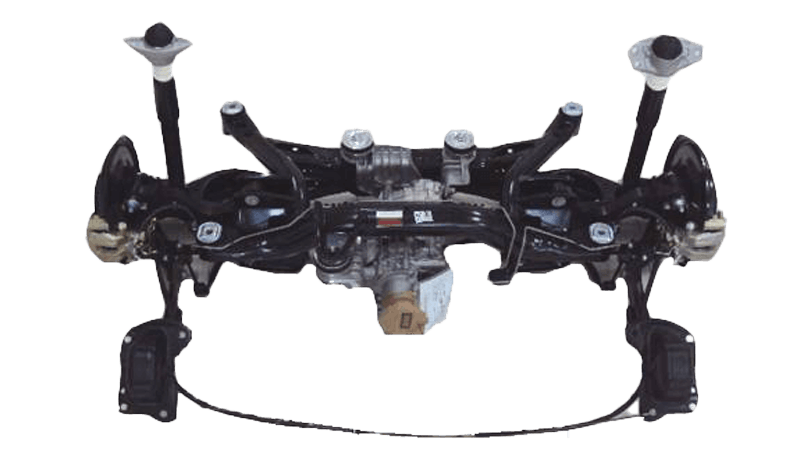

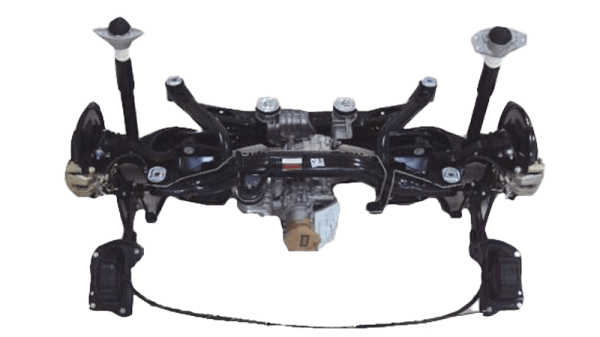

Chassis modules

If required: Integration, management, assembly and delivery of chassis modules according to customer specifications.

In various projects, either the assembly to a small subsystem is required or desired, or the assembly to a complete (ready-for-use) axle module.

New developments

Customer requests and striving for innovation: New developments on cast aluminium components.

If lightweight construction is a high/high priority, modern aluminium casting with its design possibilities offers an attractive potential. Handlebars and wheel carriers as unsprung masses not only help the overall vehicle weight. Driving subframes in one casting maximise design possibilities.

Got questions?

NBJX North America

+1 (734) 721 7340

Also of interest?

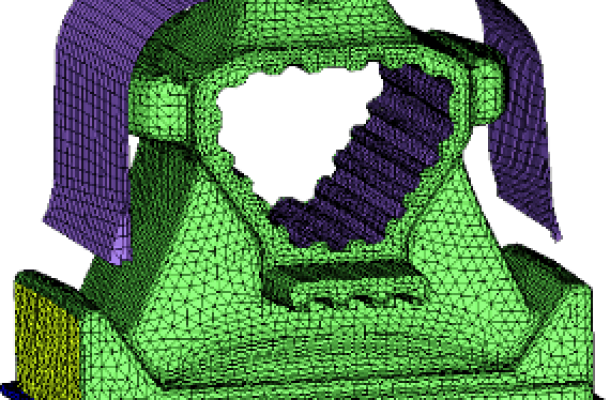

CAE: CAD & FEM

State-of-the-art technology and test tracks on the computer. Resource-saving and quick to implement.

Testing and validation